In humanity’s endless pursuit of delicious flavors, one substance has played an indispensable role—vanillin. This white to pale yellow crystalline powder, exuding a warm and sweet vanilla aroma, has revolutionized the global food, beverage, and personal care industries since its discovery in the 19th century. Today, let us delve into the fascinating world of vanillin, exploring how it evolved from a laboratory curiosity into a multibillion-dollar industry and why it has become the “invisible magician” of modern manufacturing.

I. From Aristocratic Luxury to Mass Appeal: The Century-Long Evolution of Vanillin

The story of vanilla begins in the tropical rainforests of Mexico, where Aztec nobility mixed vanilla pods with cocoa to create the earliest form of “chocolate” drink. When Spanish colonizers brought vanilla to Europe in the 16th century, it quickly became a luxury flavoring reserved for the elite. However, natural vanilla production was—and still is—extremely limited. Each vanilla orchid blooms for just one day and requires hand pollination, followed by a nine-month curing process. This scarcity kept prices exorbitantly high until 1858, when French chemist Nicolas-Théodore Gobley successfully isolated the primary aromatic compound from vanilla beans and named it vanillin, unlocking the secret behind its enchanting flavor.

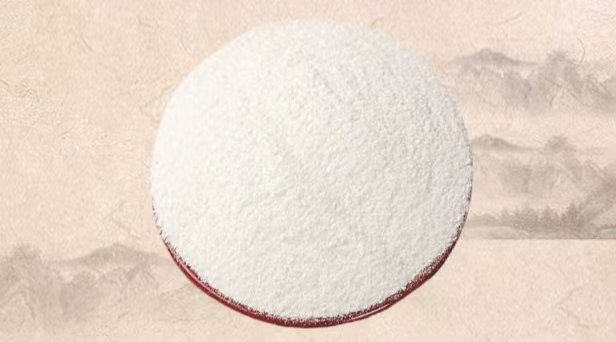

The Industrial Revolution propelled vanillin into mass production. In 1874, German scientists synthesized vanillin from conifer tree resin, marking the dawn of synthetic vanillin. By the early 20th century, chemical advancements led to large-scale production using lignin and guaiacol as raw materials, making vanillin accessible to the general public. Today, the global vanillin market is valued at $587 million (2022), with projections reaching $763 million by 2028, growing at a 4.3% CAGR. This expansion is fueled by vanillin’s widespread use across food, pharmaceuticals, and cosmetics—and its unparalleled cost efficiency, priced at just 1/50th to 1/100th of natural vanilla extract.

II. Nature Meets Laboratory: The Modern Sources of Vanillin

Contemporary vanillin production employs multiple methods, catering to diverse market demands for quality, affordability, and sustainability. Natural extraction still exists—vanilla beans from Madagascar, Indonesia, and other tropical regions undergo fermentation and drying to yield pure vanillin—but this method supplies less than 1% of global demand.

The dominant production routes include:

-

Lignin-based vanillin: Derived from a byproduct of paper manufacturing, this cost-effective method yields lower-purity vanillin.

-

Guaiacol-based vanillin: Petrochemical-derived, this high-purity synthetic vanillin dominates the market.

-

Biofermentation: Using genetically modified microbes to convert ferulic acid into vanillin, this method produces “nature-identical” vanillin with high purity and eco-friendliness. Though currently more expensive, it is rapidly gaining traction.

An emerging innovation is rice bran extraction, where enzymes break down agricultural waste to produce vanillin. The EU has approved this as a natural flavoring, offering a sustainable alternative that aligns with circular economy principles.

III. The Magician of Taste: Vanillin’s Role in Food & Beverage

Walk into any supermarket, and you’ll struggle to find a dessert aisle without vanillin. Approximately 75% of global vanillin is used in food and beverages, with ice cream, chocolate, and baked goods being the top three applications.

-

Ice cream: Adding 0.01–0.02% vanillin enhances flavor while balancing dairy richness.

-

Chocolate: The industry consumes 15% of global vanillin, using 0.005% to mask cocoa bitterness and refine taste.

-

Baked goods: Vanillin evokes homemade warmth, making industrial products feel artisanal.

Beyond flavor, vanillin has psychological and functional benefits:

-

Triggers serotonin release, enhancing pleasure (useful in low-sugar products).

-

Helps infants adapt to formula milk (at ≤20 mg/kg).

-

Acts as a sweetness enhancer, allowing 5–8% sugar reduction without compromising taste.

-

Serves as a flavor bridge, harmonizing dairy, coffee, and nut profiles.

IV. Beyond Food: Vanillin’s Hidden Role in Cosmetics & Pharma

Vanillin’s influence extends far beyond food:

-

Fragrances (34% of new perfumes in 2021 use vanillin): Creates warm, long-lasting base notes.

-

Personal care: Adds a comforting touch to lotions and soaps at 0.001–0.005%.

-

Pharmaceuticals:

-

Masks bitterness in pediatric drugs.

-

Shows anti-inflammatory and potential anticancer properties (under study).

-

-

Oral care: Combines with fluoride to fight bacteria while improving taste.

-

Tobacco (5% of vanillin use): Softens smoke harshness.

V. Cost Efficiency: The Art of Smart Vanillin Use

Vanillin is a cost-performance champion:

-

Ice cream: Natural vanilla costs $150–200/ton vs. $3–5 for vanillin (similar flavor impact).

-

Bakery: Vanillin cuts flavor costs by 12–18% with consistent quality (unlike climate-dependent vanilla).

-

Beverages: 95% retention after pasteurization (vs. <70% for natural extracts).

Advanced techniques boost efficiency:

-

Microencapsulation (30% better release control).

-

Pre-mixing with cocoa butter (15–20% less vanillin needed in chocolate).

-

Slow-release systems (8+ hours of fragrance in perfumes).

VI. Choosing the Right Vanillin: Quality Matters

Key selection criteria:

-

Food-grade: ≥99% purity, <10ppm heavy metals (FCC standards).

-

Cosmetic-grade: Optimized solubility/stability.

-

Fermented vanillin: 20–30% pricier but “natural identical” for premium products.

-

Storage: Keep at <25°C, <65% humidity, in light-proof packaging.

Why Choose Us?

With 10+ years in vanillin production, we offer:

✔ 99–99.9% purity options (synthetic & fermented).

✔ Liquid, microencapsulated, and custom formats.

✔ ISO, HALAL, KOSHER certifications.

✔ Free technical support & formulation advice.

Contact us today for samples and tailored solutions!

Leave A Comment